Select your region:

Challenges of a road construction project mastered safely

The Ruhlin Company / Shelly & Sands

The Ruhlin Company, founded by John G. Ruhlin, has been an integral part of the commercial and industrial market in Northeast Ohio since 1915. The company expanded into the civil market in 1955, constructing bridges, roads, sewers, and wastewater treatment facilities throughout the State of Ohio. In 2006, the Structural Division was added to complement the Heavy Division.

The Ruhlin Company and Shelly & Sands, Inc. selected MEVA Formwork in a Joint Venture Beltway Project in Northeast Ohio

Like MEVA, Ruhlin is a family owned and operated company. After John G. Ruhlin, his son Bill Ruhlin was named president in 1960. Ruhlin then became an ESOP in 1977. John B. Ruhlin was named president in 1980 and in 1996, James Ruhlin was named president, marking the third generation to lead the Ruhlin Company.

Much like The Ruhlin Company, Shelly & Sands, Inc., has a rich history in Northeast Ohio. The company’s first paving job started 1946 involving a small crew of six men on a road outside of the tiny town of Dresden, Ohio. Today, Shelly & Sands, Inc. serves eight major markets in three states and paves more roads in Ohio than any other company. Mar-Zane Materials, a division of Shelly & Sands, has 23 asphalt and two concrete plants producing over 3 million asphalt tons and over 200,000 cubic yards of concrete annually.

MEVA provides unique solutions for largest project in ODOT District 4’s history

In 2021, the Ohio Department of Transportation began a $160 million project to make substantial improvements around the Akron Beltway. The project included a mix of roadway improvements and bridge replacements on the I-76, I-77 and Route 8 corridor in Akron, Ohio.

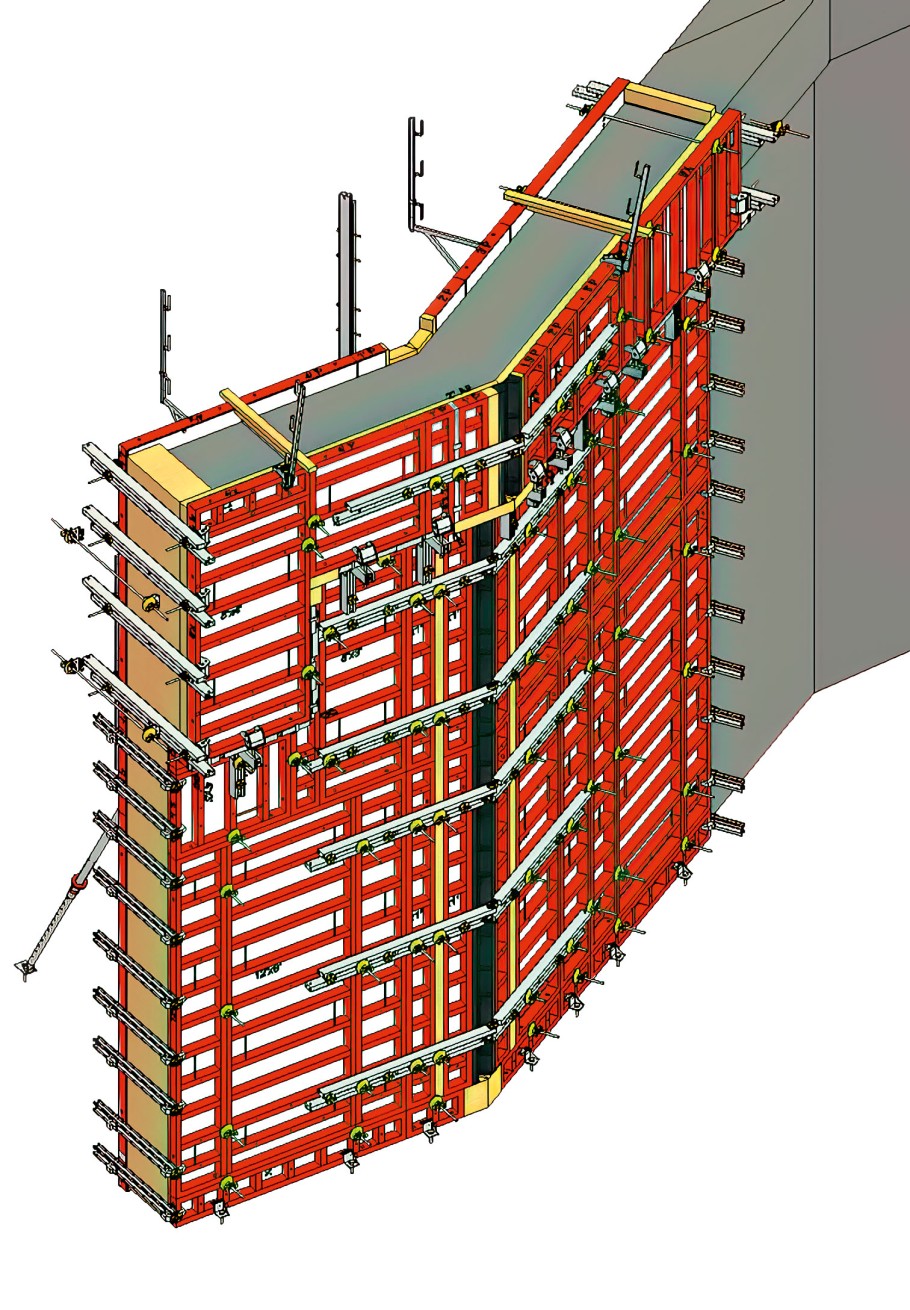

According to the ODOT District 4 Deputy Director, Gery Noirot, “This project will dramatically improve pavement and safety conditions through these routes, providing a much smoother ride for the motorists of Northeast Ohio for many years to come.” MEVA was excited to provide Ruhlin and Shelly & Sands the Imperial Formwork system along with meeting the challenges for engineering and onsite support.

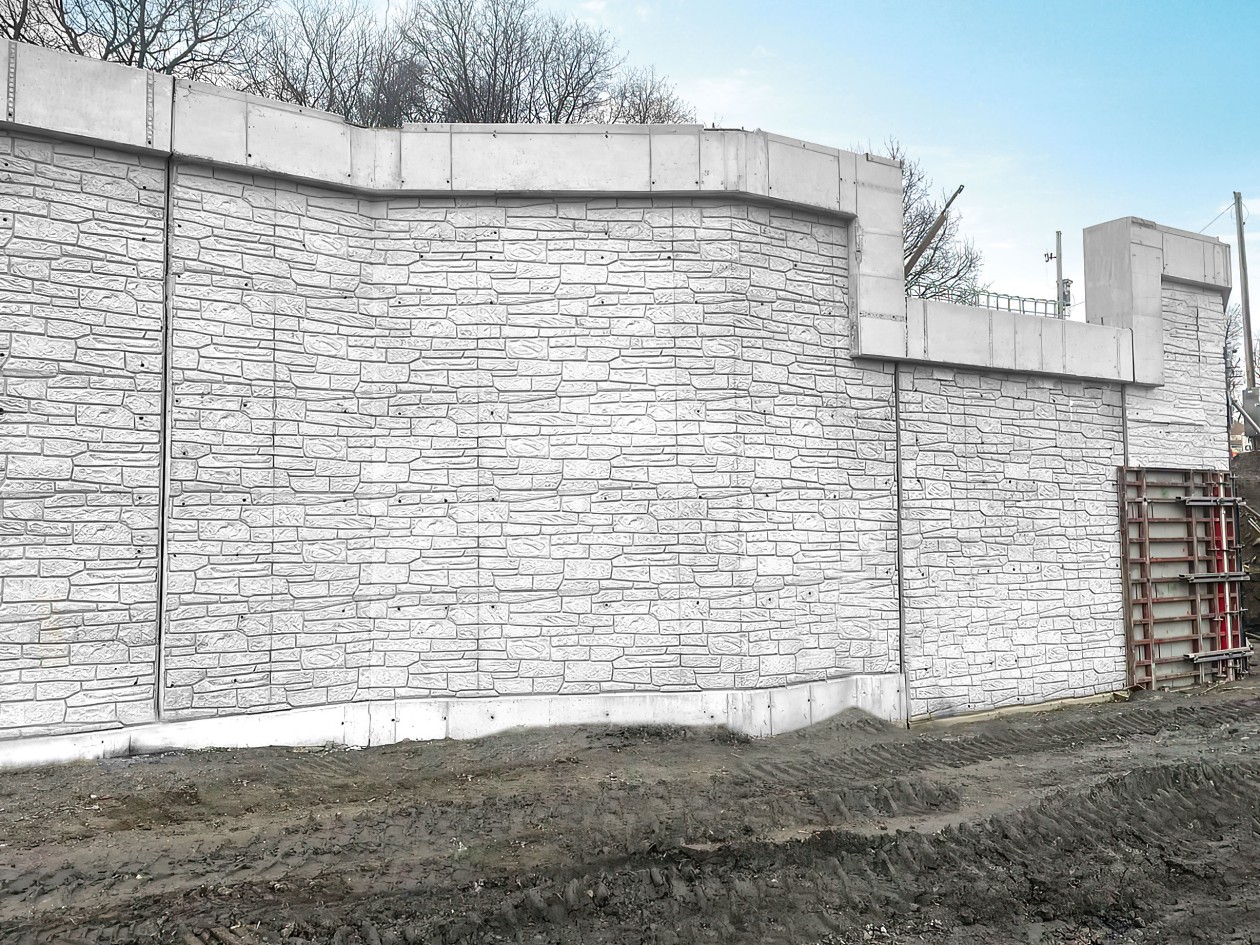

The main scope of the reconstruction project involved building retaining walls with a continuous 34” x 33” coping beam over the top of a 26” wide wall. The wall formwork below the coping was covered with a stone formliner. In the 26 ft long pour, the coping was installed without a slope. However, each wall had to step up and down to adjust the different wall heights and footing elevations. The forms were designed with the upper portion, including the coping, which was unchanged as forms cycled throughout the project. Height adjustments were then made at the bottom of the forms.

The MEVA difference

Mike Simmons, the project superintendent, has worked in the industry for 17 years and seen many different forming systems.

We used MEVA Imperial for the ease of use, versatility, and the high capacity pour rating. The knowledgeable and attentive service of Steffen Pippig during the bidding phase and construction process allowed the project to run smoothly and efficiently.

Superintendent, Mike Simmons

We would like to thank Ruhlin and Shelly & Sandys for the opportunity to support them on the project and look forward to working together to solve future concrete projects together.

Featured Products:

Project:

I-76/I-77/SR 8 Akron Beltway improvements

Contractors:

The Ruhlin Company / Shelly & Sands

Engineering and support:

MEVA USA Engineering

Got any questions about this topic?

Why not get in touch, we are here to help you.

If you want to know more about this or any other projects please use the contact form to get in touch, we would love to hear from you.

For contact details specific to this region, visit the contact us page to find out more.